blanchers

GEM Equipment manufactures custom designed rotary drum, water, steam and thermal flow blanchers for a broad range of food products, such as pasta, beans, corn, peas potatoes and other vegetables. Designs include Lab, Bi-mode and Tri-mode blanchers. They are developed with a focus on high-quality processing, plus low water and energy consumption. Capacities range from only 1-ton per hour to 30-tons per hour.

-

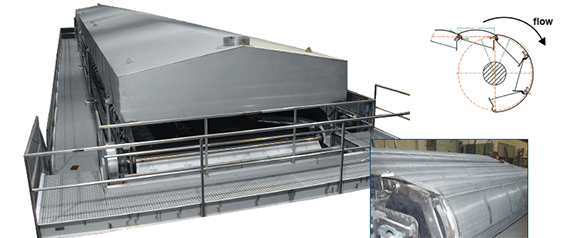

Hump Belt Blanchers

The GEM Hump Belt Blancher is designed to ensure uniform heat distribution throughout, maintain a constant steam supply and uniform temperature and provide uniform loading and spreading of product. The blancher is comprised of hump belt panels designed and manufactured by GEM. The panel forms a circular drum at the discharge, eliminating surge problems normally associated with conventional belts. The narrow, unperforated area at the edge of each panel allows more steam and air distribution. The curved panels function as flights, conveying product up steeper slopes. Each perforated panel can support a 250-pound concentrated load. The panels are easy to clean and dependable.

Rotary blanchers

The GEM Rotary Blancher processes the product using a heat transfer medium that can comprise of liquid, such as water, or gas, vapor, or a combination thereof.

The basic rotary blancher consisted of an elongate cylindrical perforate drum received in a tank filled with heated water. The product is continuously introduced through an inlet in one end of the drum and heated by the water in the tank.

During operation, flights of a helical auger in the drum rotate and moves product from the drum inlet toward a drum outlet. Inside the chamber, a heat transfer medium heats the food products preferably to blanch, cook or pasteurize them. Air and steam may be introduced into the water in the tank to help increase heat transfer and air to improve cooling in food cooling applications. Available is a CIP system for both hot and cold zones.