blanchers

GEM Blanchers are available in a wide range of designs and materials to meet your application needs. They are designed to move product efficiently and cost-effectively while protecting product integrity.

-

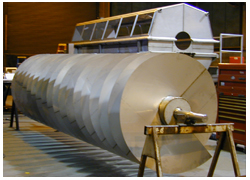

Rotary blanchers

GEM Equipment of Oregon, Inc. has been designing, building, and installing Rotary Blanchers for a wide variety of food products, such as pasta, beans, corn, peas and other vegetables by blanching or heating. GEM Equipment designs their Rotary Blanchers to be more efficient, heat product more uniformly, have lower maintenance costs, in a manner to ensure the food is not contaminated.

The GEM Rotary Blancher processes the product using a heat transfer medium that can comprise of liquid, such as water, or gas, vapor, or a combination thereof.

The basic rotary blancher consisted of an elongate cylindrical perforate drum received in a tank filled with heated water. The product is continuously introduced through an inlet in one end of the drum and heated by the water in the tank.

During operation, flights of a helical auger in the drum rotate and moves product from the drum inlet toward a drum outlet. Inside the chamber, a heat transfer medium heats the food products preferably to blanch, cook or pasteurize them. Air and steam may be introduced into the water in the tank to help increase heat transfer and air to improve cooling in food cooling applications. Available is a CIP system for both hot and cold zones.

-

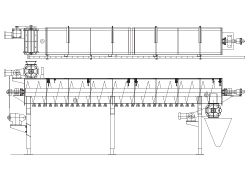

rotary screw blanchers

The Rotary Screw Blancher has an open-top screen mounted inside the pressure vessel and a rotatable auger mounted within the screen. The stainless steel tank generally has a cylindrical and perforate side wall (other designs may be oval, rectangular, etc.), which includes a blanching zone and a dewatering zone. During food processing, the screen is fixed relative to the tank and auger rotates the screen to advance the product. To clean the screen and portions of the tank, the screen may be pivoted away to a cleaning position.

The tight tolerance between the screen the auger reduces damage to the product as it passes through the screen, yet the clearance gap is sufficient to prevent metal-to-metal contact.

-

rotary steam blanchers

The Rotary Steam Blancher’s drum is rotatably mounted within the inner tank and an auger therein. It includes a steam recirculation system for maintaining a uniform temperature pattern within the blancher. Usually, rotary blanchers use hot water, or a combination of hot water and injected steam to heat the product by cooking or blanching. The drum is rotatably mounted in a generally cylindrical, open-top tank. The tank is fitted with a cover for minimizing heat loss and for enclosing the drum for safety reasons, and which can be opened for maintenance and cleaning. The tank is made from stainless steel or another suitable material for food processing applications. The perforations in the sidewall that extend completely through the sidewall allows steam to pass from the inner compartment and into the drum. An auger within the drum rotates with drum to advance the food